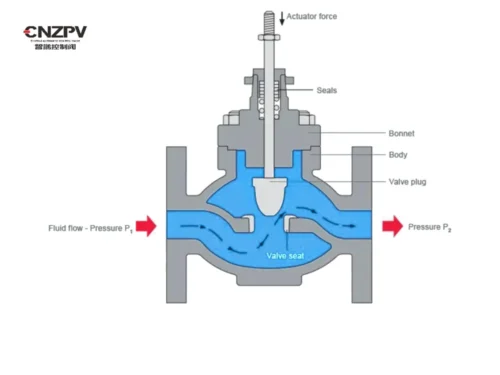

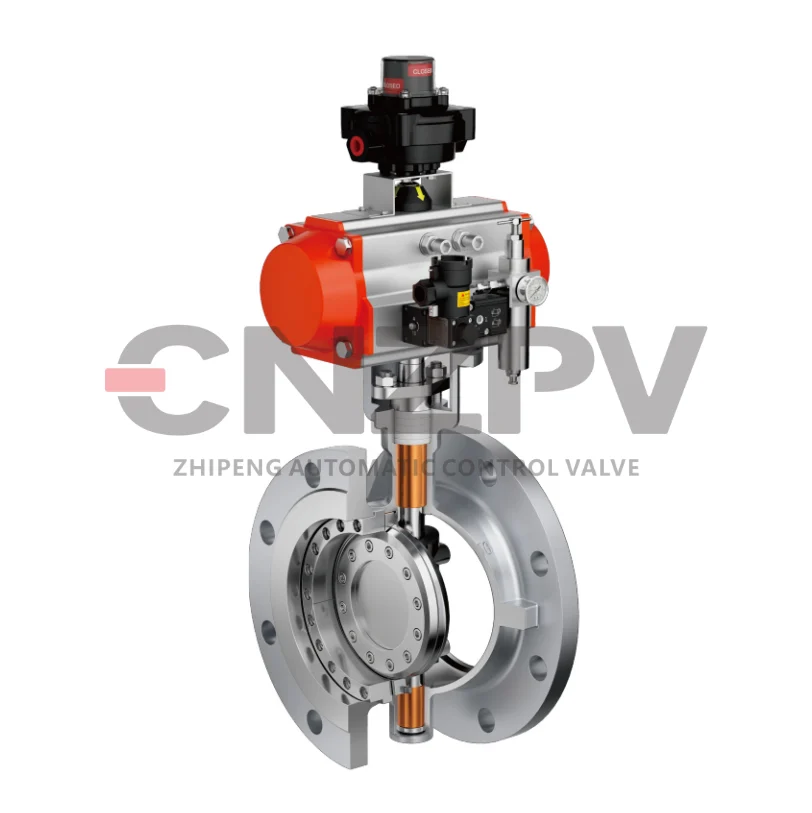

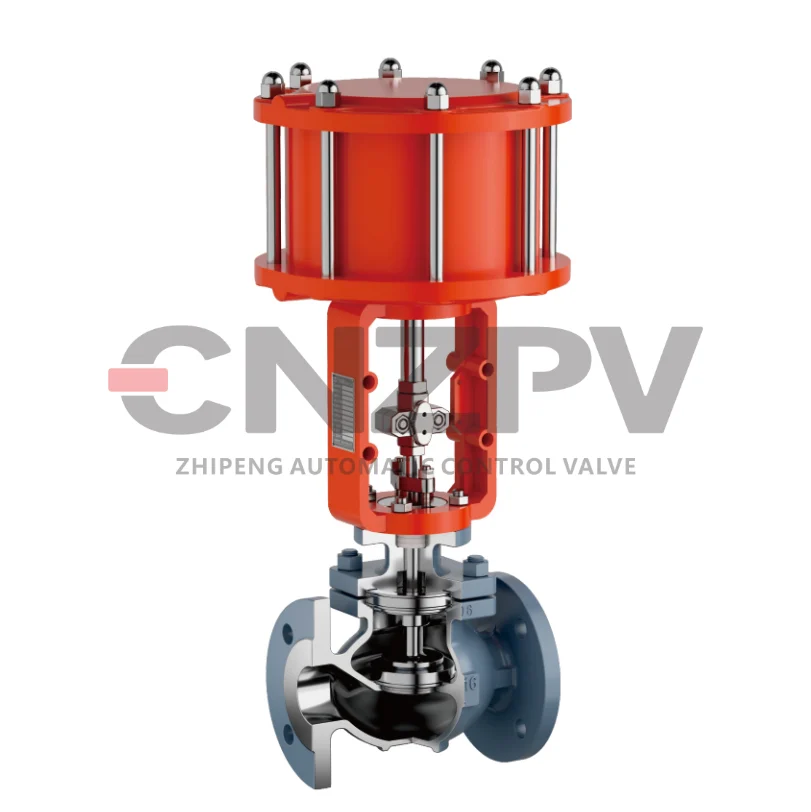

Pneumatic valves are among the equipment widely used in various industries in recent years. They are driven by compressed air to open and close.

Pneumatic actuators can easily achieve rapid linear cyclic motion. They have a simple structure and are easy to maintain. Moreover, they can be used in various harsh working environments, such as those with explosion – proof requirements, much dust, or high humidity. They are mainly applied in industries like petroleum, natural gas, chemical engineering, electric power, printing and dyeing, mining, and pharmaceuticals.

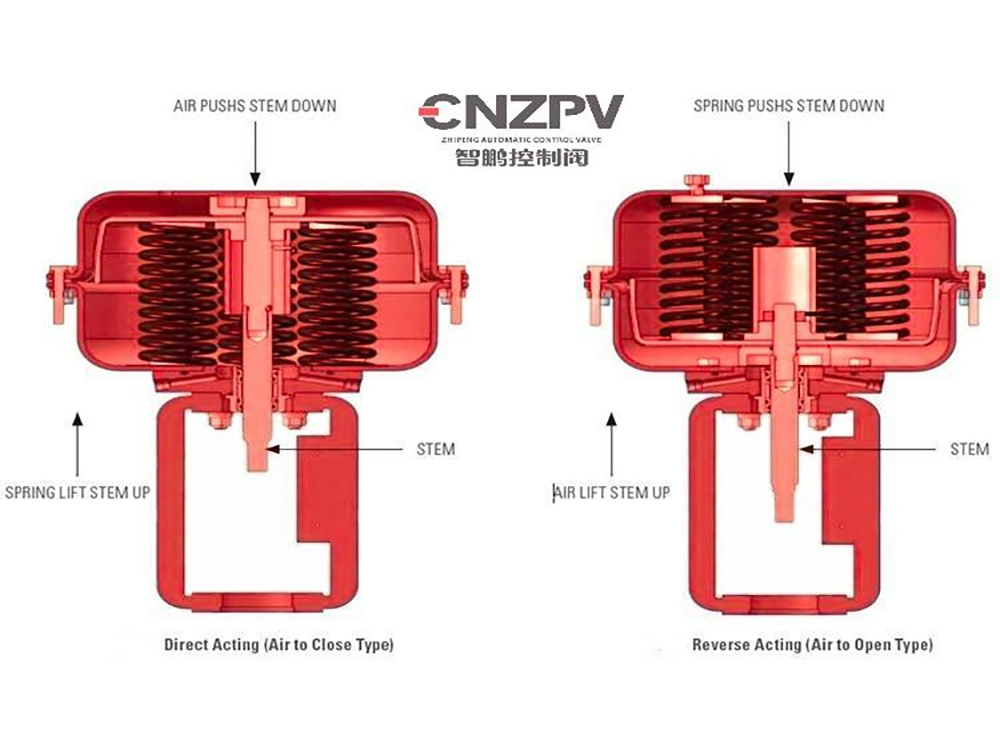

Pneumatic valves can generally be classified into Air-To-Open type and Air-To-Close type according to their action modes. The choice between Air-To-Open and Air-To-Close is made from the perspective of process production safety. When the air source is cut off, it needs to be determined whether it is safer for the valve to be in the closed position or the open position.

For the Air-To-Open type, when the air pressure on the diaphragm cylinder increases, the valve opens wider. When the upper limit of the input air pressure is reached, the valve is fully open. Conversely, when the air pressure decreases, the valve closes. When there is no input air, the valve is fully closed. Therefore, the Air-To-Open type valve is sometimes also called the Fail-To-Close type (FC).

The Air-To-Close type has an action direction opposite to that of the Air-To- Open type. When the air pressure increases, the valve closes; when the air pressure decreases or there is no air pressure, the valve opens or remains fully open. So, it is sometimes also called the Fail-To-Open type (FO).

During operation, several common fault positions are (FO, FC, FL). In the case of valve failure to close or open, the “fault” refers to the valve’s action when there is an air source failure. For the fault positions of pneumatic valves, there are mainly the following situations:

1.In the case of the interlocking action of the pneumatic valve device, the valve positions are as follows:

FC – When the air source is lost, the valve is in the closed position.

FO – When the air source is lost, the valve is in the open position.

FL – When the air source is lost, the valve remains in its current position all the time.

FLC – When the air source is lost, the valve maintains its position but tends to close, and eventually the valve is in the closed position (when the gas in the cylinder is consumed).

FLO – When the air source is lost, the valve maintains its position but tends to open, and eventually the valve is in the open position (when the gas in the cylinder is consumed).

2.In the case where the regulating valve or O-Off valve participates in the interlocking action of the device, the valve positions are as follows:

FC – When the air source is lost or the solenoid valve loses power, the valve is in the closed position.

FO – When the air source is lost or the solenoid valve loses power, the valve is in the open position.

AFL/EFC – 1. When the air source is lost but the solenoid valve does not lose power, the valve maintains its position; 2. Regardless of whether the air source is lost, when the solenoid valve loses power, the valve is in the closed position.

AFL/EFO – 1. When the air source is lost but the solenoid valve does not lose power, the valve maintains its position; 2. Regardless of whether the air source is lost, when the solenoid valve loses power, the valve is in the open position.

3.Pneumatic valves achieve functions such as valve cut – off, connection, and regulation through output signals. Their opening and closing speeds are relatively fast. They are often used for rapid two – position cut – off and can also be used for flow regulation. With different accessories, various control methods can be achieved.