Meta Description: Ensure proper control valve operation with our step-by-step FAT guide covering ANSI/ISA 75.25, ISO 5208, and API 6D compliant testing procedures for valve positioning & pneumatic actuator alignment.

Control Valve Pre-Shipment Verification: Critical Checks

Proper validation of valve trim position and actuator direction is mandatory per IEC 60534-8 to prevent field failures. Below are certified inspection protocols:

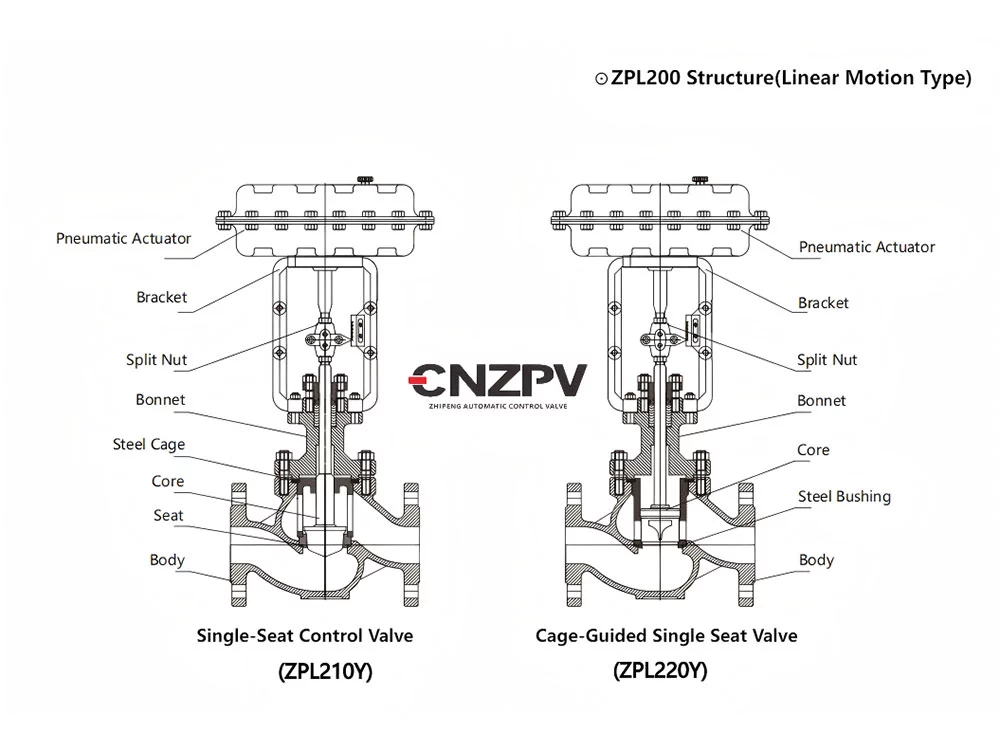

1. Valve Trim Position Verification

1.1 Manual Operation Test

Complies with ISO 5208 Class IV leakage standards

Tools:

Handwheel (for gearbox actuators)

Manual override (pneumatic actuators)

Torque wrench (electric actuators)

Procedure:

Closed Position (0%):

Verify stem reaches mechanical stop

Perform bubble-tight test using 0.6 MPa air (ANSI/FCI 70-2)

Open Position (100%):

Confirm full travel per ISA 75.11 stroke specs

Check flow path obstruction via compressed air purge

1.2 Stroke Calibration

Meets IEC 60534-3 linearity requirements

Equipment:

Dial indicator (accuracy ±0.1mm)

HART communicator (for smart positioners)

Tolerance:

Linear valves: ±1% of rated travel (e.g., 25mm → ±0.25mm)

Rotary valves: ±1° for 90° travel

1.3 Limit Switch Adjustment

Certified to EN 60947-5-1

Mechanical switches:

Set NO/NC contacts to trigger at 95-100% travel

Proximity sensors:

Adjust sensing gap per manufacturer’s datasheet (typically 2mm)

2. Pneumatic Actuator Direction Validation

2.1 Action Types (Per API 6D Annex F)

| Type | Signal Action | Fail-Safe Mode | Application |

| Air-to-Open (ATO) | Air ↑ → Valve opens | Fail-Closed (FC) | Cooling water systems |

| Air-to-Close (ATC) | Air ↑ → Valve closes | Fail-Open (FO) | Fuel gas emergency lines |

2.2 Direction Test Protocol

Follows ISO 5211 mounting standards

Supply 0.5 MPa air via FRL unit (Filter-Regulator-Lubricator)

Observe stem movement:

Extending stem = ATO action

Retracting stem = ATC action

For reverse action: Swap Port A ↔ Port B connections

2.3 Troubleshooting Guide

| Issue | Root Cause | Corrective Action |

| Travel ≠ 4-20mA signal | Improper span calibration | Recalibrate using HART 375/475 communicator |

| Wrong fail-safe position | Incorrect spring assembly | Reconfigure per EN 15714-3 guidelines |

3. FAT Checklist (API 6D Appendix A)

Mechanical inspection: Smooth operation with ≤2 Nm friction torque

Seat leakage test: Max 50 bubbles/min (ANSI Class IV)

Stroke verification: 3 full cycles at 20%/50%/100% signals

Direction confirmation: P&ID vs. actual movement cross-check

4. Key Compliance Notes

Explosive atmospheres: ATEX Directive 2014/34/EU Category 2G/3G

Materials: NACE MR0175 for H₂S service

Documentation: Include test certificates per ISO 10474 3.1B