Fluorine-lined control valves are critical components in industries such as chemical processing, oil & gas, and water treatment. Selecting the right manufacturer is essential to ensure product quality, reliability, and long-term performance. Here are some key factors to consider when choosing a reliable manufacturer for fluorine-lined control valves.

1. Industry Experience and Expertise

Look for a manufacturer with a proven track record in producing fluorine-lined control valves.Check how many years they have been in business and whether they specialize in valves for your industry.Experience often translates to better product design, quality control, and problem-solving capabilities.

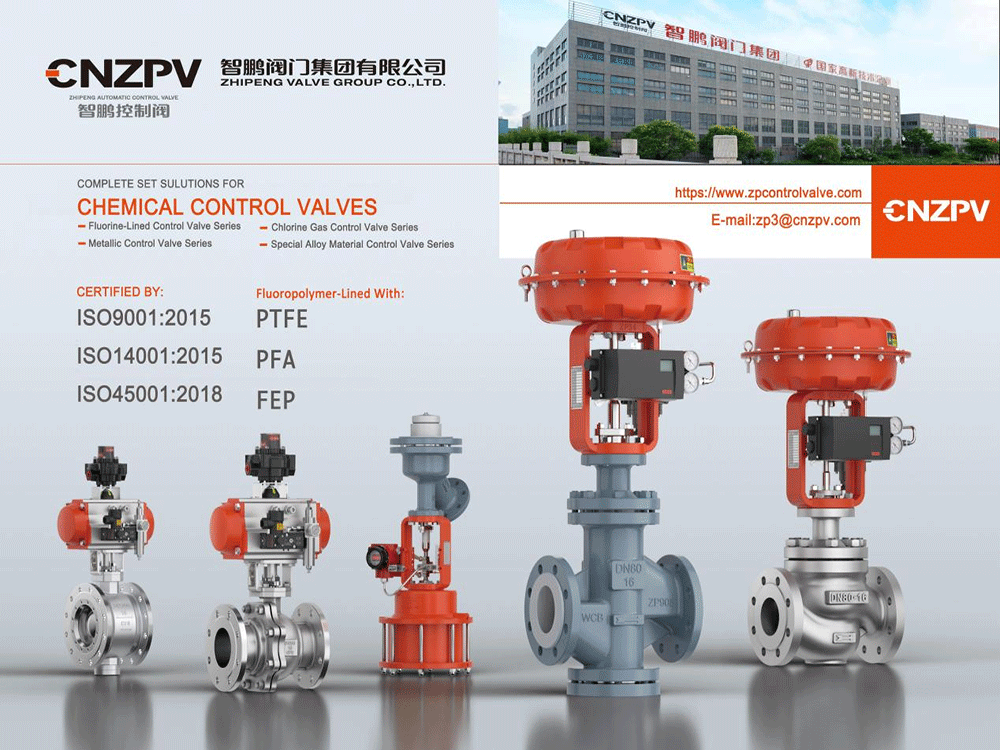

2. Product Quality and Certifications

Ensure the manufacturer adheres to international quality standards, such as ISO 9001.Verify if their products have necessary certifications (e.g., API, CE, TRCU) for your target market.Request information about their quality control processes, including material selection, testing, and inspection procedures.

3. Customization Capabilities

A reliable manufacturer should offer customized solutions to meet your specific requirements.Check if they can provide tailored designs for size, pressure rating, temperature range, and material compatibility.Customization ensures that the valves will perform optimally in your unique operating conditions.

4. Technical Support and After-Sales Service

Choose a manufacturer that provides comprehensive technical support, from product selection to installation guidance.Inquire about their after-sales services, including maintenance, repair, and spare parts availability.Reliable support minimizes downtime and ensures long-term operational efficiency.

5. Production Capacity and Lead Times

Assess the manufacturer’s production capacity to ensure they can meet your order volume and delivery deadlines.Discuss lead times and their ability to handle urgent orders or unexpected demand spikes.A manufacturer with efficient production processes can help you avoid delays and keep your operations running smoothly.

6. Reputation and Customer Reviews

Research the manufacturer’s reputation in the industry by reading customer reviews and testimonials.Look for case studies or references from companies in your sector.A strong reputation is a good indicator of reliability and customer satisfaction.

7. Cost-Effectiveness

While price is an important factor, it should not be the sole deciding factor.Compare the total cost of ownership, including product quality, durability, and after-sales support.A slightly higher upfront cost may save you money in the long run by reducing maintenance and replacement expenses.

8. Visit the Manufacturing Facility

If possible, arrange a visit to the manufacturer’s facility to inspect their production processes, equipment, and quality control measures.A firsthand look can provide valuable insights into their capabilities and commitment to quality.

Conclusion

Choosing the right manufacturer for fluorine-lined control valves is a critical decision that impacts the efficiency and reliability of your operations. By considering factors such as industry experience, product quality, customization capabilities, and after-sales support, you can find a reliable partner who meets your needs.

At CNZPV, we pride ourselves on delivering high-quality fluorine-lined control valves tailored to your requirements. Contact us today to learn more about our products and services.